Building structure around sustainability in safe storage

Within the safe storage industry sector, sustainability is being addressed in different ways, with a smaller number of manufacturers such as Gunnebo...

4 min read

Jacob Naslund : Dec 9, 2025 1:25:09 PM

As the world looks for cleaner energy alternatives to meet climate goals, hydrogen is increasingly emerging as a promising solution. From fuelling heavy industry like steel production to powering vehicles or heating homes, hydrogen offers potential if produced sustainably.

You might have heard of green, blue, pink, or even turquoise hydrogen, and you might wonder: how can a colourless gas come in so many colours? In this article, we break down the hydrogen rainbow - from green to grey and everything in between - explaining how each type is produced, what it costs, and how sustainable it really is.

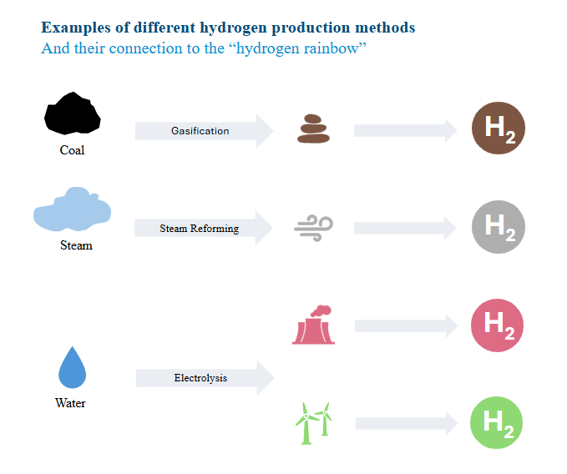

The “hydrogen rainbow” refers to the different ways hydrogen is produced. Each colour refers to a different production method, each with a distinct environmental footprint, especially in terms of CO₂e emissions. While there’s no universal standard for these names, here’s a practical guide to the main colours in the rainbow.

Green hydrogen is produced through the electrolysis of water, using electricity generated entirely from renewable sources like solar or wind. This process emits no carbon dioxide, making green hydrogen the most environmentally friendly option available today. However, it is also the most expensive form of hydrogen due to the current costs of renewable energy infrastructure and electrolysis technology, with a price ranging from around €3–8¹/kg1. As these technologies mature and scale, prices are expected to come down. Green hydrogen is often considered the long-term gold standard for a sustainable hydrogen economy.

Pink hydrogen is generated through electrolysis powered by nuclear energy. While public opinion on nuclear varies, from a carbon emissions standpoint this process is extremely low-impact. Pink hydrogen has the advantage of being stable in output, unlike renewables which fluctuate with weather. The cost is currently estimated to be between €3-6²/kg of H₂ produced, depending on local energy systems, and it holds strong potential as a scalable, low-emission solution.

Yellow hydrogen is also made via electrolysis, but the electricity specifically comes from solar power. It is sometimes treated as a subset of green hydrogen but earns its own label due to the dedicated use of solar energy. With emissions that are very low and production costs slightly below that of green hydrogen, yellow hydrogen is gaining attention, especially in regions with abundant sunlight. Its sustainability potential is high, although it is dependent on the carbon footprint of the solar power used.

Turquoise hydrogen is produced through methane pyrolysis, a process that breaks methane down into hydrogen and solid carbon. If powered by renewable electricity and paired with long-term carbon storage or use of the solid carbon, it could be a low-emission solution. However, the technology is still in development and has not been proven at scale. It sits between blue and green hydrogen in terms of potential sustainability and cost-effectiveness.

Blue hydrogen is produced from natural gas via a method known as steam methane reforming, but unlike grey hydrogen, it includes carbon capture and storage (CCS) to trap much of the resulting CO₂. It is often marketed as “low-carbon hydrogen,” although some emissions do still occur in the process. Blue hydrogen is more affordable than green hydrogen and can serve as a transitional solution as cleaner technologies scale. However, its reliance on fossil fuels and the long-term viability of carbon storage remain concerns.

White hydrogen refers to naturally occurring hydrogen found in underground deposits. This form of hydrogen is not produced through any industrial process but is instead extracted. Commercial-scale extraction methods are still in early stages. Since it occurs naturally, it could be a game-changer in terms of sustainability, but as of now, there are no proven strategies for large-scale use, and the environmental impact of extraction is not yet fully known.

Grey hydrogen is currently the most widely produced type globally. It is created through steam reforming of natural gas, a process that releases significant amounts of CO₂. Unlike blue hydrogen, grey hydrogen does not use any carbon capture technologies. Its popularity comes down to cost, (it's relatively cheap to produce) but its environmental impact is high, making it less desirable in a world aiming for carbon neutrality.

Brown hydrogen is made from lignite, or brown coal, using a gasification process. This method emits very high levels of carbon dioxide and is one of the least sustainable hydrogen production methods. Despite its environmental drawbacks, some projects (such as in Australia) have explored brown hydrogen for export due to existing coal infrastructure. However, its use is increasingly viewed as incompatible with long-term climate goals.

Similar to brown hydrogen, black hydrogen is derived from black coal and also relies on gasification. It results in extremely high CO₂ emissions and is among the most polluting forms of hydrogen. Like brown hydrogen, it is largely viewed as outdated for a sustainable future, but remains in limited use where coal resources are abundant and alternatives are not yet in place.

As hydrogen technologies evolve, decision-makers increasingly face a trade-off between sustainability and cost. Each colour on the hydrogen spectrum represents a trade-off. Green and pink hydrogen are the cleanest options, but cost is still a barrier. Grey and brown hydrogen are inexpensive but environmentally damaging. Blue and turquoise hydrogen sit in the middle, offering reduced emissions at more manageable costs, though neither is fully climate-neutral. White hydrogen, meanwhile, remains a wild card.

When mapped on a chart of cost versus emissions, no type yet occupies the “sweet spot” of being both clean and cheap. The expectation is that, as technology matures, infrastructure scales, and carbon pricing takes hold, more production methods will move closer to this ideal balance.

The lower-left corner of the chart, low cost and low emissions, is the ideal target zone. However, no hydrogen type currently sits there.

As production technologies scale and carbon pricing matures, we can expect the dots on this chart to shift. Ideally, more options will move toward that “sweet spot,” delivering clean hydrogen at a competitive price.

Despite growing interest in sustainable hydrogen, the global market is still dominated by fossil-based production. As illustrated in the chart, grey hydrogen accounts for over 80% of all hydrogen today. Brown hydrogen, made from coal, makes up another 13%. In contrast, low-emission alternatives like green, blue, and yellow hydrogen collectively represent just a small fraction, together below 4%. This highlights the significant shift still needed to decarbonise hydrogen production at scale.

The way we produce hydrogen determines whether it’s part of the solution, or part of the problem. As hydrogen becomes more central in energy systems, especially in industrial applications like steelmaking, understanding these colours helps us track how sustainable a hydrogen project really is.

From policymakers to engineers, many are now pushing for hydrogen strategies that prioritise green and other low-emission variants. But economics, infrastructure, and energy availability still influence what’s feasible in different regions.

As infrastructure expands and technologies improve, the hydrogen rainbow may simplify or evolve. But for now, it remains a useful guide to navigating the complexity of hydrogen production.

For hydrogen to live up to its promise, cleaner methods must become both affordable and scalable. That means stronger investment in renewables, improvements in electrolysis efficiency, effective carbon capture, and clear international standards.

Ultimately, in sectors such as steelmaking, where emissions are notoriously hard to cut, hydrogen offers one of the few viable pathways to deep decarbonisation, provided it’s produced cleanly and at scale.

Within the safe storage industry sector, sustainability is being addressed in different ways, with a smaller number of manufacturers such as Gunnebo...

Sustainability is increasingly important for businesses to consider as they plan for the future. Rising global temperatures, new regulations and...

At Gunnebo Safe Storage, regulatory compliance plays an important role in how we protect both people and the environment. Two key frameworks we...